Value-Added Services

Conversion Services

Our value-added options allow us to customize steel to meet each customer’s desired product properties.

Steelmaking services are included with most of the product we sell. We also offer conversion services like rolling, piercing, and thermal treatments. Our excess capacity in steel conversion capabilities creates an opportunity for customers to benefit from these services with steel from other sources.

Our Conversion Capabilities

Rolling

Our rolling mills have the capacity and breadth of capability to roll bars in sizes that range from 1” through 16”. In addition to rolling the carbon and alloy steels we melt, our mills are also capable of processing stainless and other grades of steel melted outside our facilities.

Stress Relieve and Temper

Metallus has multiple continuous quench-and-temper lines for bar and tube products, which are capable of meeting the most stringent specifications. We recently invested in our Advanced Quench-and-Temper Facility at our Gambrinus plant, which combines some of the most advanced equipment in quench-and-temper with Metallus’ decades of operating experience. This investment enhances our ability to serve exacting requirements in the oil and gas, and industrial markets.

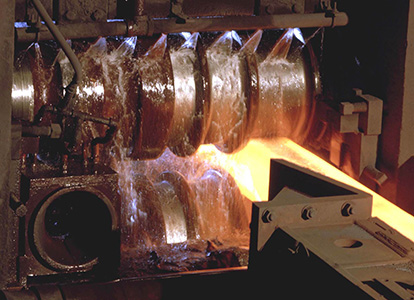

Piercing

Metallus ships well over 100,000 tons of tubing per year. Our two piercing mills produce tubes from 3” to 13” and outer diameter to wall ratios from 3:1 up to 10:1. We pierce other stainless grades and we have pierced non-ferrous metals, including titanium. Using our piercing mills often offers significant cost advantages over machined tubes, especially for expensive metals like titanium.

Contact Us

For more details about our thermal treat offerings, call 330-471-8888.

Need more help?